Notícias

Drills

In a drilling operation, the drill machine is responsible by moving the drill, which is responsible for material removal. For drilling operations the drill more used is the twist drill, but still aware of this there are a number of drills for many different purposes.

The Twist Drill

The twist drill is attached to the machine by its shank that can be cylindrical or conical shape. The cutting part receives its fundamental form, thanks to two slots of helical shape. The two main cutting edges formed by the sharpening of the tip are responsible for cutting the material, while the edge cross, which lies between the two faces incident, constrict the stuff out so it consumes about 40% of the feed force.

The choice of drill

In choosing the drill should be considered the following factors:

Other types of drills

The Twist Drill

The twist drill is attached to the machine by its shank that can be cylindrical or conical shape. The cutting part receives its fundamental form, thanks to two slots of helical shape. The two main cutting edges formed by the sharpening of the tip are responsible for cutting the material, while the edge cross, which lies between the two faces incident, constrict the stuff out so it consumes about 40% of the feed force.

The choice of drill

In choosing the drill should be considered the following factors:

- the diameter of the hole to be opened

- the material being drilled and

- the sharpening of the drill.

Other types of drills

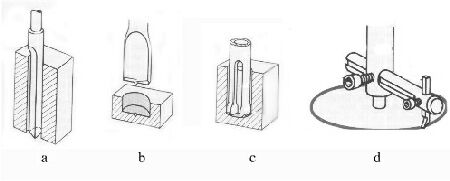

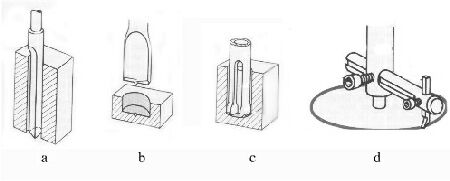

- Gun Drill: Represented in the picture "a". Works with a single edge. Suitable for running deep holes;

- Drill center: Representing the image "b ". It is used when the holes should be with a flat bottom. It has a tip that serves as a guide;

- Hollow drill: Represented in image "c ". Used to cut a core material;

- Drill Cut: Represented in image "d ". It is used to part discs.

Gostou? Então compartilhe:

Notícias relacionadas